Rebar is usually a fundamental metal bar or block that may be commonly utilised in reinforced concrete and reinforced masonry structures. These rebars are usually made from carbon steel and might be recounted as reinforcing steel or perhaps reinforcement. Below Structural BIM Products and services Rebar detailing is really a discipline of creating fabrication or shop drawings of steel reinforcement for that design method. The internet site fabrication drawings that transpire for being created determined by design drawings for reinforcing metal are Rebar Specific drawings. Engineers and Architects make style and design drawings to create the desired strengths determined by the rebar detailing giving you with diameter, bar shapes, portions, period of bars to aid the website for steering clear of delays and wastage thus rushing your overall construction procedure.

Every single rebar is thorough symbolizing a shape, size, and diameter determined by the requirements in the structure drawing. The Rebar placement will then be revealed intimately which indicates the concrete go over, specific site, and Distinctive approach to placement as required. The rebar aspects and bar bending schedules might have bar diameter, bar notation, the quantity of bars, body weight in the bars, and size of Every single bar and mentioning the entire weight to the total pair of bars placed inside the drawing. Throughout the preparation of rebar details, the inventory lengths of bars are held in see to be certain There's no wastage with the product.

Rebar Detailing and Reinforcement concrete detailing is now modeled and made in 3-dimension using the 3D Modelling technological know-how like BIM Modelling Expert services. The specialized rebar detailing software program like Rebar CAD and AutoCAD beneficial for this purpose may well assistance each individual member with the structural engineering to prepare designs, document, track, and In general control.

Possessing comprehended the elemental idea of rebar detailing a bit of structural BIM modeling, let's try and see the significance about it in the whole design approach is. Some while in the factors are:

Importance of Rebar detailing in Structural BIM Modeling

Though second drawings and bending schedules are very likely to be established and presented, the 3D model is Furthermore issued to all or any they associates starting from the consulting engineer and contractor departments all the way down to the metal fixers that occur to become within the floor stage on-web page. The mix of such two grow to be Specially a good selection for web page staff in which web page limitations or congestion of reinforcements keep on being unknown until finally you will discover reinforcement and fixation on-web-site. For every single bar, the entire position of repairing is shown inside 3D design along with any hindrances or obstructions.

Building detailing reinforcements in 3D within the second procedure is not simply speedier but modeling rebar inside the 3-dimensional setting helps eliminate clashes. Even though modeling one can visualize if any with the bars have a tendency not to deal with in a decided area, therefore recognize These types of clashes inside rebar drawings. There may be the facility to investigate the reinforcement in total detail as staying a precise element illustration prior to it's staying purchased from the fabricator and complex cages are assembled off-web-site.

When you will discover the right rebar detailing Option accessible, a competent and accurate reinforcement model may be created by importing structural calculations from a structural analysis application. With Automation concerned modifications are generally mirrored within 3D rebar detailing in addition to needed updates to drawings and schedules swiftly when improvements are created in other places unlike acquiring to finish manual variations to second sections and views.

Rather than based on manual input from paper schedules, the rebar fabricator can extract data specifically throughout the design for that equipment. The concrete pours may very well be very well-described In the model together with other specifics like portions and volumes to be sure more precision in controlling material deliveries. This will permit better control and end in a lot less wastage and decreasing of General charges.

Owning 3D in depth electronic models is just not going to limit the benefit to the solitary-phase like that from your engineering and detailing stage but is usually used from all phases. Possessing reinforcement fully modeled in 3D, the contractor is assured that it will in good shape into areas in the event the time will come so that it's fastened on-web page. The information in the model might be utilized inside of area to allow contractors to carry out a design-dependent structure by making use of robotic complete station equipment together here with tracking rebar and elements and determining the place and when they're going to be essential.

Fixers current on-web site can search Within the product setting on the rebar detailing to accurately understand its software, i.e. what is actually needed when and the place versus depending on their interpretation of regular second drawings.

The structural engineers can certainly moreover much more quickly deliver layout experiences, schedules, and drawings from a 3D product as as opposed with 2nd styles, thereby enhancing style performance. There is much more precision in price tag projection according to the rebar quantities made through the 3D model simply because they are a lot more reliable when compared to the second drawing take-offs. Not merely this the quantities are wholly traceable, making it possible for comparisons and checks staying executed simply.

Using these reasons, we could conclude that Rebar Detailing a self-control of Structural BIM Modelling Products and services is but a person Together with the important requirements for that General achievement within the venture lifetime cycle. To summarize, obtaining Rebar Detailing the rebar contractor can concentrate on creating rebars and there won't be any will have to estimate reinforcement needs for procurements at the web site because of economical 3D products. The design will depict the requirement for anchors and laps inside the drawings thereby making sure style and design adequacy in addition to minimizing wastage. The general waste and time delays are lessened at the web site for the reason that every one of the condition drawings is usually readily available. Depending on these details the bars could possibly be easily fabricated according to the designs and quantity of bars necessary.

Mara Wilson Then & Now!

Mara Wilson Then & Now! Joshua Jackson Then & Now!

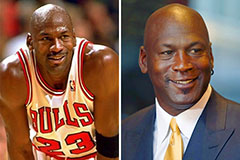

Joshua Jackson Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now! Teri Hatcher Then & Now!

Teri Hatcher Then & Now!